Punch and Shear Machine

Punch and Shear Machine

Punch and Shear Machine video

|

Demand table loading...

|

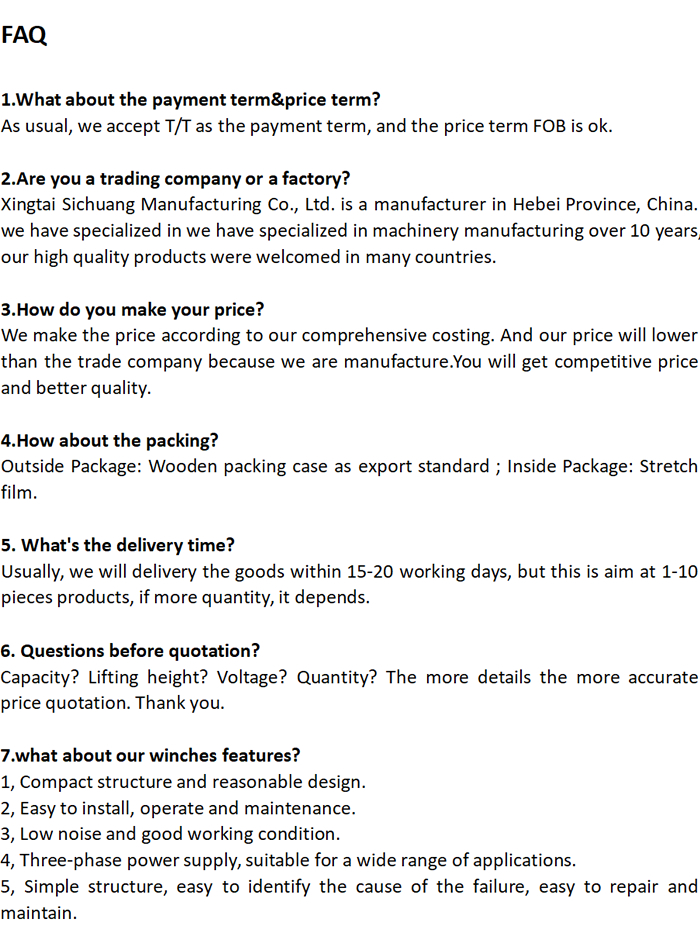

Punch and Shear Machine Description

Combined punching and shearing machine is a machine tool equipment integrating multiple functions such as metal shearing, punching, plate shearing and bending. It has the advantages of simple operation, low energy consumption, low maintenance cost, light weight, small volume, low noise and high efficiency. It is the preferred equipment for metal processing in modern manufacturing industries (such as metallurgy, bridge, communication, electric power, military industry and so on). Combined punching and shearing machine is divided into hydraulic combined punching and shearing machine and mechanical combined punching and shearing machine. Combined punching and shearing machine is an ideal punching and shearing equipment with small body, powerful function and simple and perfect appearance; The biggest advantages of the multifunctional punching and shearing machine are simple operation, flexible movement, high punching and shearing efficiency, smooth and traceless section, very low failure rate and long service life.

Operation steps of multifunctional combined punching and shearing machine:

1. Check the power supply, the voltage is stable, there is no phase loss, and the leakage protector and air switch are in good condition.

2. Wiring, open the wiring cabinet of the combined punching and shearing machine, connect the wire and close the cabinet door.

3. After power on, press the foot switch, the machine does not act, exchange the power lines, and check whether the emergency stop switch is on.

4. Connected to foot pedal switch.

5. When working, pay attention to turn off the power every time you change the mold

6. After work, turn off the switch, turn off the main power switch, skim off the power line and clean the debris.

Precautions for operation of multifunctional punching and shearing machine:

1. Before start-up, check whether the transmission parts, connecting screws and pin shafts of the punching and shearing machine are loose. Whether the electrical grounding is intact.

2. Lubricate all parts before work, start up and test run for two to three minutes, and put them into operation only if there is no problem.

3. Overload is not allowed, and punching and shearing of quenched steel is strictly prohibited.

4. Wear gloves and labor protection articles during work, and sandals and slippers are strictly prohibited.

5. When punching and shearing, always refuel the punching tools to prevent the upper and lower punching tools from skewing.

6. Pay attention to the safety of fingers during feeding, especially when the sheet metal can not be pressed by the last presser foot, punching and shearing is prohibited.

7. It is strictly forbidden to disassemble and calibrate the cutting edge and stamping die when driving. It is not allowed to knock the die, shear blade and other parts.

8. The specification range of sheet metal shall be strictly controlled, and punching and shearing are strictly prohibited when it is exceeded.

9. Other articles and a large amount of flushing materials shall not be stacked in the workplace, and the vehicle must be stopped during adjustment and cleaning.

10. After the work is completed, shut down and cut off the power in time, and clean the site.

Maintenance code of combined punching and shearing machine:

1. Operate in strict accordance with the operating procedures.

2. Before each startup, add lubricating oil regularly, at a fixed point and quantitatively according to the requirements of the lubrication chart. The oil shall be clean and free of precipitation.

3. The plate shears must always be kept clean, and the unpainted parts must be protected from anti rust grease.

4. The lubricating oil in the motor bearing shall be replaced and filled regularly, and the electrical part shall be regularly checked for normal operation, safety and reliability.

5. Frequently check whether the triangular belt, handle, knob and key of the plate shear are damaged. If they are seriously worn, they shall be replaced in time and reported to the spare parts for supplement.

6. Regularly check and repair switches, fuses and handles to ensure their reliable operation.

7. Lubricate and scrub the machine tool 10 minutes before work every day.

|

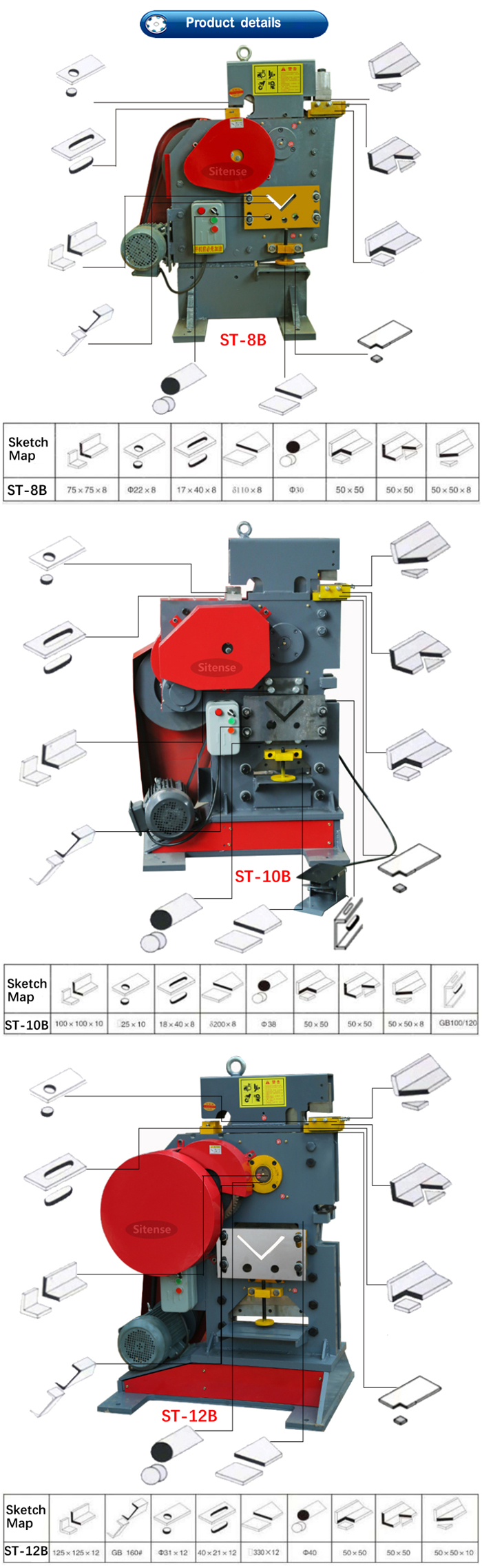

Model |

ST-8B |

ST-10B |

ST-12B |

|

Tool travel |

27mm |

30mm |

36mm |

|

Input voltage |

380V |

380V |

380V |

|

Motor power |

2200W |

3000W |

4000W |

|

Shear strength |

360KN |

500KN |

900KN |

|

Efficiency |

30times/min |

30times/min |

30times/min |

|

Weight |

550Kg |

700Kg |

1100Kg |

|

Size |

90*60*110cm |

90*60*125cm |

110*60*1450cm |

Punch and Shear Machine News

|

Demand table loading...

|