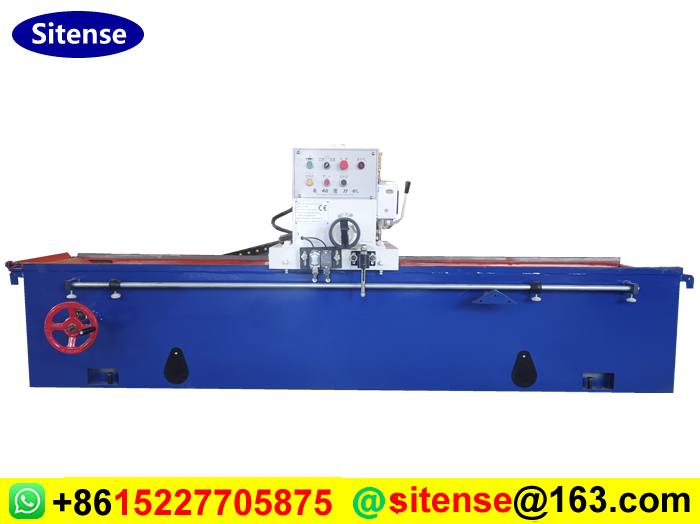

Knife Sharpener

Knife Sharpener

Knife Sharpener video

|

Demand table loading...

|

Knife Sharpener Description

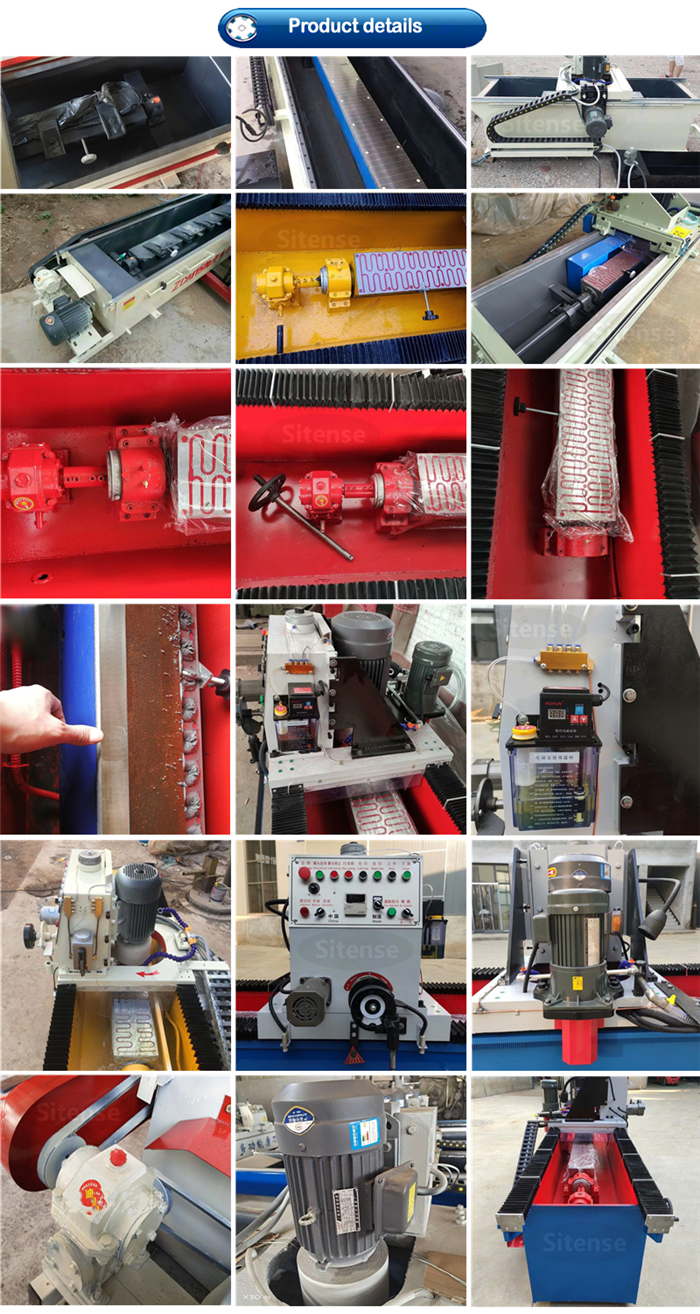

CNC electromagnetic knife grinder is mainly used for polishing and grinding of various straight cutting tools and straight workpieces. The body of the knife grinder is a closed welding structure, which greatly improves the strength of the body and effectively prolongs its service life. The transmission part of the knife grinder is rack transmission, which overcomes the disadvantage of uneven speed and greatly improves the stability and reliability of the knife grinder. The cutter grinder also adopts the design of automatic feeding, which effectively improves the degree of automation, saves the manpower and time required for manual feeding, and improves the labor intensity of the operator.

Our company's electromagnetic knife grinder adopts a reinforced bed and track, with smooth operation, sharp tool grinding, smooth and elegant appearance, and scientific structural design. Widely used in various straight edged cutting tools such as paper cutters, scraper blades, shredder knives, and crushing knives.

The characteristics of CNC electromagnetic grinding machine:

1. The suction is uniform, the blade is not easily deformed, and the grinding is more straight.

2. Convenient operation and higher work efficiency.

3. It has a delayed demagnetization function, reliable positioning, and safer operation.

4. The design of the grinding machine body has changed from a loose frame structure to a steel plate enclosed welded structure. Greatly improving the strength of the body and extending its service life.

5. For the collective of welded steel plate metal materials, sufficient vibration aging treatment process is adopted, which significantly reduces the degree of natural deformation of the entire machine after processing.

6. The transmission part has changed from belt transmission to rack and pinion transmission, overcoming the uneven landing point of walking speed and ensuring its reliability and stability.

7. The original design changed the swinging rotation angle of the grinding head of the grinding machine from 30 ° to a swinging rotation angle greater than 90 °, making it more convenient and faster to move up and down the workpiece and replace the grinding wheel.

8. The automatic feed design is adopted during the grinding process, which improves the degree of automation. Effectively saving manpower and time required for manual feeding, improving the operator's level of labor.

|

Press Plate Type Knife Grinding Machine |

||||

|

Model |

ST-1500 |

ST-1800 |

ST-2200 |

ST-2600 |

|

Machining length |

1500mm |

1800mm |

2200mm |

2600mm |

|

Grinding head speed |

30m/min |

30m/min |

30m/min |

30m/min |

|

Main motor |

3.0kw |

3.0kw |

3.0kw |

4.0kw |

|

Traveling motor |

1.1kw |

1.1kw |

1.1kw |

1.1kw |

|

Water pump motor |

60w |

60w |

60w |

60w |

|

Grinding wheel speed |

1440r/min |

1440r/min |

1440r/min |

1440r/min |

|

Grinding head |

Cup grinding wheel(Diameter:200mm;Wall thickness:20mm;Height:110mm) |

|||

|

Worktable size |

1470*170mm |

1470*170mm |

1470*170mm |

1470*170mm |

|

Dimension |

2900*850*950mm |

3200*850*950mm |

3600*850*950mm |

4000*850*950mm |

|

Weight |

380kg |

460kg |

600kg |

900kg |

|

Electromagnetic Knife Grinding Machine |

|||||

|

Model |

ST-1600 |

ST-1800 |

ST-2300 |

ST-2600 |

ST-3200 |

|

Machining length |

1600mm |

1800mm |

2300mm |

2600mm |

3200mm |

|

Grinding head speed |

30m/min |

30m/min |

30m/min |

30m/min |

30m/min |

|

Main motor |

4.0kw |

4.0kw |

4.0kw |

5.5kw |

5.5kw |

|

Traveling motor |

0.75kw Variable frequency motor |

||||

|

Water pump motor |

90w |

90w |

90w |

90w |

|

|

Lifting motor |

300w |

300w |

300w |

300w |

300w |

|

Grinding wheel speed |

1440r/min |

1440r/min |

1440r/min |

1440r/min |

1440r/min |

|

Grinding head |

Cup grinding wheel(Diameter:200mm;Wall thickness:20mm;Height:110mm) |

||||

|

Worktable size |

1470*170mm |

1470*170mm |

1470*170mm |

1470*170mm |

1470*170mm |

|

Dimension(mm) |

3000*1000*1100 |

3250*1000*1100 |

3650*1000*1100 |

4100*1000*1100 |

4700*1000*1100 |

|

Weight |

1100kg |

1200kg |

1350kg |

1600kg |

2000kg |

Knife Sharpener News

- 2024-08-21 Maintenance Method For Electromagnetic Knife Grinder

- 2024-08-21 The Structural Characteristics Of The Electromagnetic Knife Sharpener

- 2024-08-21 The Usage Method Of Electromagnetic Knife Grinder

|

Demand table loading...

|